1- جنس کلیه قطعات فانوس تماماً از مواد اولیه کاملاً مرغوب (Carbonate) زرد، سبز و قرمز گرید مخصوص چراغهای راهنمایی میباشد.

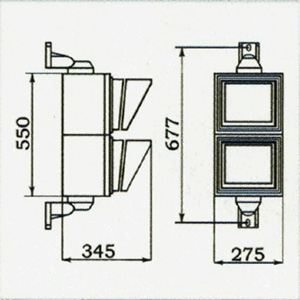

2- فانوس شامل دوخانه مجزا که توسط بست فلزی مخصوص به هم متصل میشود و در بالا و پایین دوعدد پایه فانوس ( کرپی ) جهت اتصال به دکل چراغ راهنمایی با قابلیت تنظیم زاویه دید و عبورکابل ازمیان آن که با بست مخصوص به آن متصل شده است .

3- اندازه هر خانه تقریبا 180×275×275 میلیمتر با اندازه لنز حدود210×210 میلیمتر که 195×195میلیمتر آن درمعرض دید می باشد .

4- هرخانه برروی لنز دارای نقاب سه وجه با عمق 155 میلیمتر است .

5- هرخانه فانوس از قطعات زیر تشکیل شده است :

1-5 – بدنه

2-5- درب که به شکل لولائی به بدنه محکم می شود ودارای نوار پلاستیکی جهت آب بندی ومحل قرارگیری لنز ورفکلتور می باشد .

3-5- لنز در دو رنگ سبز و قرمز و بصورت دولایه می باشد که درهر لایه یک آدمک ایستاده ( لنز قرمز ) ویک آدمک درحال حرکت ( لنز سبز ) قرارمیگیرد وجهت انکسار و یکنواخت شدن نورخروجی و ثابت نگه داشتن آدمکها از لنزی شفاف که دارای برجستگیهائی درسطح داخلی می باشد و با بست مخصوص محکم میگردد استفاده شده است .

4- 5- رفلکتور که جهت پرتاب نور به بیرون به درب متصل شده با گرید مخصوص چراغ راهنمایی از جنس PC و دارای سطح داخلی آیینه ای با پوشش آلومینیم ( متالایزینگ ) می باشد و در انتها به سرپیچ چینی که به آن محکم شده ختم می شود .

6-سرپیچها توسط سیم 5/1 افشان مجزا به رنگهای سبز وقرمز جهت فاز خانه های سبز و قرمز و آبی جهت نول به ترمینال واقع درخانه پایین ( سبز) متصل می شود .

7- پایه های فانوس ( کرپی ) از PC گرید مخصوص چراغ راهنمایی ساخته شده است .

8- تمامی قطعات درصورت لزوم به راحتی قابل باز وبسته شدن وتعویض می باشد .

9- تمامی قطعات متحرک که امکان نفوذ آب ویا گرد وغبار به داخل چراغ را دارند دارای واشر ارتجاعی آب بندی می باشند بطوریکه ضمن اطمینان از استحکام نصب ، امکان ورود آب و گرد و غبار به داخل چراغ میسر نمی باشد .

10- تمامی ابعاد ومشخصات اپتیکی طبق استاندارد های تعریف شده معتبر اروپا یی می باشد .

11- سرپیچ از نوع بسیار مرغوب چینی است ودرسیم کشی داخلی از سیم افشان استاندارد وکلاف بندی شده بصورتی کاملا اصولی که امکان اتصال یا خطر برق گرفتگی وجود نداشته باشداستفاده شده است .

12- پایه های نصب ومحل اتصال آنها به بدنه فانوس با قالبگیری دقیق به نحوی است که امکان تنظیم دقیق ( 5 درجه ) درحول محورعمودی را برای کسب بهترین بازده به صورت کاملامحکم وغیر قابل تغییر فراهم می آورد وپس از نصب هیچگونه تنش خمشی یا پیچشی به چراغ اعمال نمی نماید.

13- فانوسها دربرابر مواد معدنی ، اشعه خورشید (UV) و بارانهای اسیدی بسیار مقاوم بوده ودچار تغییر رنگ دربرابر نورخورشید نمی گردد.

14- فانوسها دربرابر سرما وگرما مقاوم بوده ، تحمل حرارتی 35- تا 85+ درجه سانتیگراد را دارا می باشند .

15- فانوسها از مواد پلیمری قابل بازیافت تشکیل شده وباعث آلودگی محیط زیست نمی گردد .

16- برروی کلیه قطعات اصلی تقویم تولید ، جنس مواد اولیه ، نام وآرم شرکت نوبرپارت حک شده است .

17- حداقل IP برای تستهای حفاظتی ( گرد وغباروآب ) که درآزمایشگاه معتبر براساس استاندارد IEC529 انجام پذیرفته عدد 53 می باشد ونتایج تستهای حفاظتی قابل ارائه می باشند .

18- کیفیت وکارائی کل چراغ به مدت یکسال ضمانت میگردد وبرای حداقل عمر 5 سال طراحی و ساخته شده است .

Reviews

There are no reviews yet.